Environmental Impacts of the Paper Industry

Wisconsin is the United States largest paper producer and has been for years. Collectively the paper industry, including pulp, paper and converting companies, constitutes the fifth largest manufacturing sector in the state, providing thousands of high-paying jobs. Unfortunately, the environment, and our democracy, has suffered because of it.

Contaminated Sediments

The paper industry has been a major source of accumulated toxic chemicals in several rivers in Wisconsin, most notably of PCBs to the Fox River and Green Bay in northeast Wisconsin. As a result of recycling PCB-containing carbonless copy paper, area mill operations discharged about 250,000 pounds of PCB's contaminating the sediment in the lower Fox River. According to the Wisconsin Department of Health Services an estimated 160,000 pounds of PCB's left the river and entered Green Bay and Lake Michigan by 2006. The EPA further estimated in 1998 that an additional 600 pounds were flushed from the Fox River sediment each year until clean up occurred.

Since 1985, the Clean Water Action Council has been fighting to get PCBs removed from the river. CWAC has pushed for removal over simply capping because floods could flush additional thousands of pounds into the Bay of Green Bay. Once PCBs are released into the bay and Lake Michigan, they would be extremely difficult, if not impossible, to recover, according to the EPA. In May 2013, U.S. District Judge Griesbach issued a significant ruling finding that the government can require any of the seven companies to do all of the remaining work or any portions of that work.

The Lower Fox River PCB Clean-Up Project that began in 2006 has officially finished with the EPA certifying the closure of the project at the beginning of 2023. The project was completed with the help of the DNR, EPA, U.S. Fish & Wildlife Service, tribal nations, and the corporations responsible for the clean-up and the care of the river and bay. In total, the project removed 6.5 million cubic parts of contaminated sediment accomplished through hydraulic dredging, with engineered caps installed on another 275 acres of riverbed. Long-term testing for PCBs will continue, but thus far test results show significant reductions in PCB concentration levels compared to the measurements conducted in 2006.

Continuing Toxic Pollution

The paper industry is one of the major sources of toxic chemical pollution in Wisconsin. The federal and state Toxic Release Inventories shows releases of approximately 14.7 million pounds of known toxic substances between 2019 and 2021. Modest reductions in chemical use over the years (per unit of production) seem to be countered by increased production.

Many toxic chemicals are used in paper making, especially toxic solvents and chlorine compounds used to bleach and delignify pulp. Additional toxins are used as biocides to prevent bacterial growth in the pulp and finished paper products. (In the past, toxic mercury compounds were used as biocides, contributing to Wisconsin's mercury contamination problems in fish.) [See Toxic Pollution]

Conventional Air Pollution

Pulp and paper mills are large sources of standard air pollutants, such as carbon dioxide, nitrous oxides, sulfur dioxides, carbon monoxides and particulates. These contribute to ozone warnings, acid rain, global warming, and respiratory problems. Many of the mills are large enough to have their own coal-fired power plants, raising additional concerns about mercury, arsenic, and radioactive emissions. More recent reports suggest a trend of declining air pollution throughout the entire state of Wisconsin; however Northeast Wisconsin cities remain at a disadvantage for regulating air pollution due to the large number of industries remaining in the area like paper companies. [see Air Pollution]

Energy Consumption

Papermaking is energy intensive, drawing large amounts of electricity from public utilities, or forcing mills to build their own power plants. This is a significant contributor to the air pollution in our region, and to the hidden damages due to fuel extraction at the source (oil drilling, oil spills, coal mining, pipelines, transmission lines, etc.).

Many companies in Wisconsin are moving to reduce the energy demand required to produce paper, with Green-Bay Packaging (GBP) as a significant leader in this change. GBP uses an anaerobic digester system to pre-treat and recycle their water. The anaerobic digestion system reduces their COD (chemical oxygen demand) by 80%, which saves the company 35,000 Kilowatts daily. Additionally, GBP captures methane and other biogases from the digestion process, which allows for the reduction of their natural gas usage by 4%. The company’s goal is to eventually replace 10% of their natural gas usage with these preserved biogases. (see Energy)

Water Consumption

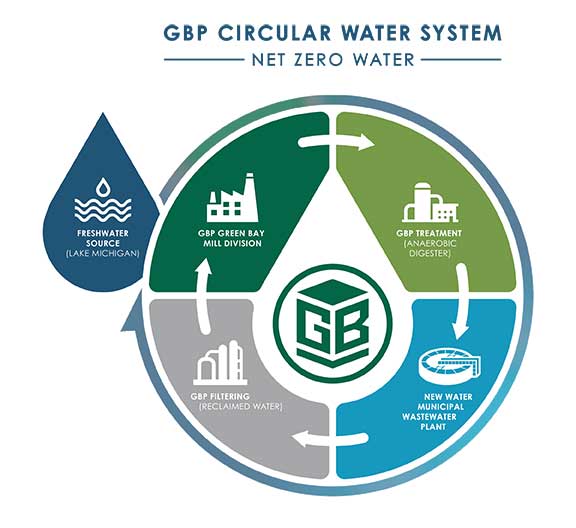

A shift towards “Net Zero Water” can be seen within the paper industry. Georgia-Pacific's Green Bay mill filters water from the Fox River and then returns it to the river in a cleaner state according to their public relations department. Green Bay Packaging's newly constructed Green Bay mill is the first in the world to be certified as meeting the net zero water requirements by Underwriter Laboratories (UL). The concept for net zero water usage relies on the freshwater input to the mill being completely offset by alternative water use. “Alternative” water sources originate from inside the process, and a volume of water at least equal to what was used is cleaned and returned to the original body of water.

There are two key concepts that are fundamental to the success of the Net Zero approach. One, to use as little water as possible in the process, and second to re-use water as often as possible. Re-using water in paper mills is more complicated than continually running the same water over and over through the mill. For the water to be usable, it must remain below certain levels of bacteria, sediment, and a variety of other contaminants. GBP utilizes a system of biological, chemical, and mechanical separation which allows water to be treated on-site so that it can be reused.

Additionally, GBP seeks every possible method to reduce their water demand. By collecting storm water from mill roofs and parking areas and removing 80% of the total suspended solids from the water allows these additional water sources to be utilized in the manufacturing process, preventing any water being sent as effluent to the Fox River. Some water from GBP does become degraded to the point it can no longer be reused, but that effluent undergoes anaerobic treatment to remove pollutants to the point that municipal plants can handle it, where it then treated and discharged to the river.

Solid Waste

Papermaking generally produces a large amount of solid waste. Unfortunately, landfilling costs in northeast Wisconsin are relatively cheap (often less than $27 per ton), so the industry has little incentive for making more efficient use of its materials. Because we have so many paper recycling industries in our area, an even larger quantity of waste is generated. Paper fibers can be recycled only a limited number of times before they become too short or weak to make high quality paper. This means the broken, low-quality fibers are separated out to become waste sludge.

All the inks, dyes, coatings, pigments, staples, and "stickies" (tape, plastic films, etc.) are also washed off the recycled fibers to join the waste solids. The shiny finish on glossy magazine-type paper is produced using a fine kaolin clay coating, which also becomes solid waste during recycling. These paper mill sludges consume a large percentage of our local landfill space each year. Worse yet, some of the wastes are land spread on cropland as a disposal technique, raising concerns about trace contaminants building up in soil or running off into area lakes and streams. Some companies burn their sludge in incinerators, contributing to our serious air pollution problems, including the release of dioxin.

More recycling has been made available to the paper industry based on improved techniques and technology. Green Bay Packaging’s new plant allows them to recycle paper stock that previously could not be used, while simultaneously being more efficient with the paper stock they use compared to past efforts. Additionally, the ability to now recycle “mixed” paper, much of which was formerly doomed for the landfill, has helped contribute to the doubling of production capacity. Increasing fiber recovery also makes more efficient recycling of all paper used and produced in paper mills, again reducing the number of products ending up in landfills.

Deforestation

Worldwide, enormous tracts of virgin forest are being felled for paper pulp production, contributing to the world's tragic deforestation trends. Many Wisconsin mills import their pulp and undoubtedly some of this pulp came from old-growth endangered forests. Citizen networks have formed worldwide in an effort to save the last of these precious, irreplaceable places. (Trees may be renewable, but ancient forest plant and animal communities are often not renewable because of the complex ecological balance that was built over thousands, even millions, of years in some of these forests.)

Corruption of Democracy

Paper is king in Wisconsin, literally. For many decades, the industry has been pampered by local, state, and federal governments -- with tax breaks, energy breaks, incentive grants, university research projects, employee training programs, cheap water, cheap pulpwood, cheap landfills, and other generous subsidies. The paper industry is an example of corporate control over state government. The paper industry gives generously to political campaigns and is rewarded.

For 30 years, the paper industry successfully blocked the Fox River PCB cleanup, and they have been extremely influential in weakening Wisconsin's air, water, and solid waste regulations since the beginnings of those programs.

Overtime, proposals for new environmental standards has been met with less resistance from the paper industry. Many companies are even taking responsibility for their past actions that have harmed the environment and are working closely with other organizations to reverse the harm they have done.

The acknowledgement that public health protection, natural resource conservation, and environmental sustainability are achievable while continuing to make profits, has encouraged more companies to rethink their operations for producing paper products. Not all problems are solved through these new efforts, but there is growing optimism that Wisconsin's paper industry can be more sustainable.

For more information:

Wisconsin’s Paper Industry - https://wedc.org/wisconsins-paper-industry-still-leads-the-nation-wedc-study-finds__trashed/

Wisconsin’s Air Pollution and Quality - https://www.iqair.com/us/usa/wisconsin

Fox River Cleanup Status (additions) - https://wisconsinexaminer.com/brief/lower-fox-river-pcb-clean-up-project-officially-complete/

https://dnr.wisconsin.gov/topic/FoxRiver/Background.html

Pollution - https://edap.epa.gov/public/extensions/TRIToxicsTracker/TRIToxicsTracker.html#continue

Sustainability in the Paper Industry - https://gbp.com/corporate/sustainability/